Objective, Mission & Vision

VISION OF THE COMPANY

To be the World's no.1 manufacturer of Brake Disc & Drum.

To achieve this vision every employees gives their best to the company in achieving this vision.

MISSION OF THE COMPANY

1. The main mission of the company is to provide high customer satisfaction because in this business customer satisfaction plays a very important roll.

This will helps R.M.Engineering to create value in the market.

2. Improving quality, performance, stability, & delivery in the company.

3. Every year double growth in production & profit, Increasing quality level.

4. Full Fill the India’s requirement with specific standard & quality.

5. Believe on Innovation, Best Quality & including some more addition in market product & Services.

OBJECTIVE OF THE COMPANY

1. To reduce the customer complains.2. To reduce the cost of product manufacturing.

3. To rejection, re-work and process variations.

4. To improve product and process performance.

History

has grown steadily to become a leading Brake Discs, Drums & Hubs Supplier to OEMs & OESs operating in India. We have with design, development and manufacturing capability that matches global standards in quality and safety. Our technical capability lies in over 12 years of experience and highly skilled manpower. For us quality comes first and price is secondary.

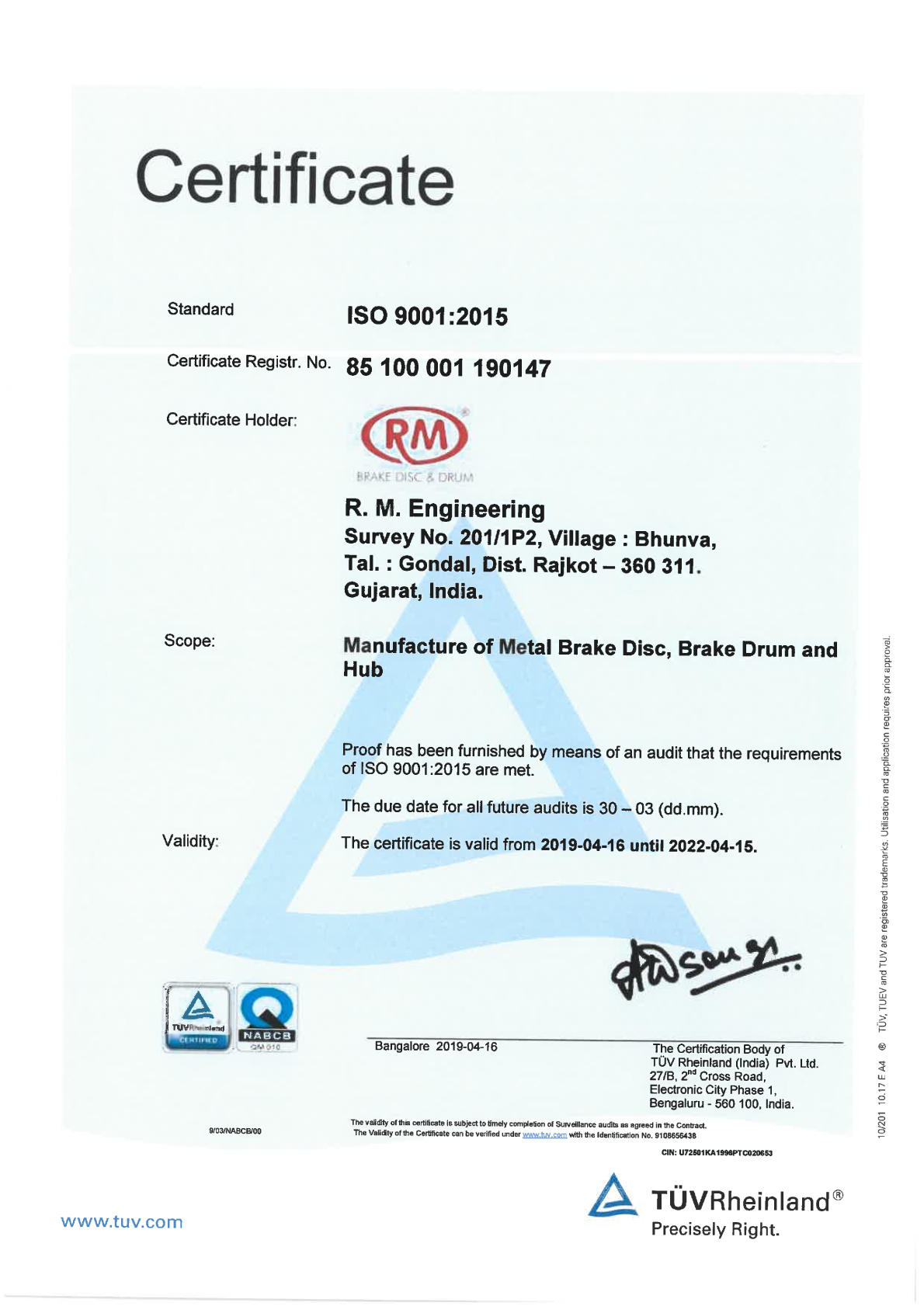

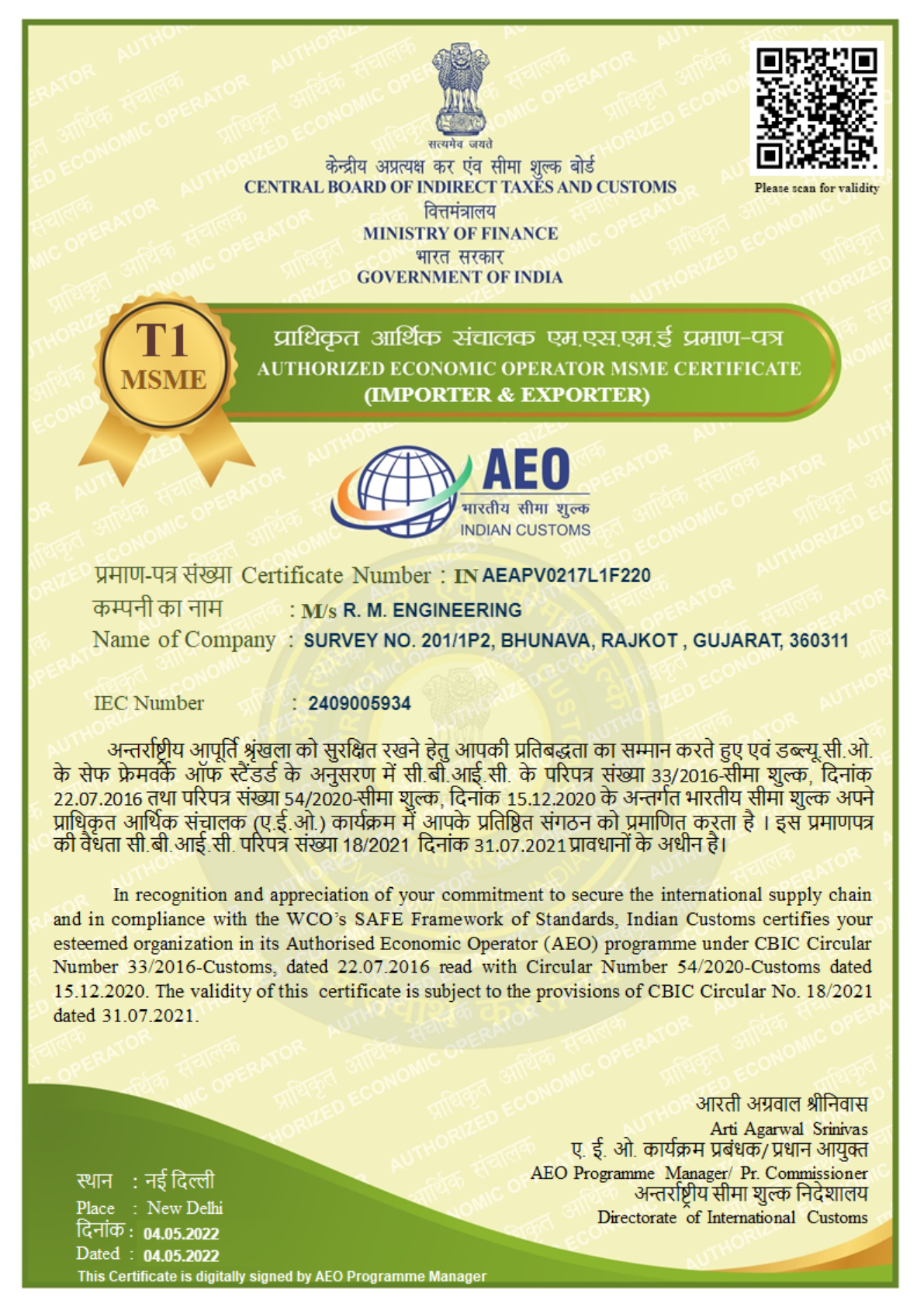

Company Profile

R. M. Engineering is the leading manufacturer of Brake Discs & Drums in India for the automotive industry. Established in 5th – May – 2005, R. M. Engineering has grown steadily to become a leading Brake Disc & Drums supplier to OEMs & OESs operating in India. With design, development and manufacturing capability that matches global standards in quality and safety, R. M. Engineering is capable of providing full Brake Discs & Drums technology from concept to completion.

The strength of R. M. Engineering India lies in its ability to motivate and harness the capabilities of its human resource, develop and nurture a strong vendor base, its commitment to quality, cost, delivery, safety and customer satisfaction.

R. M. Engineering pays particular attention to quality of products, processes, and services, and benchmarks against global quality standards. Empowered continuous improvement teams constantly strive to improve productivity, quality, cost, delivery, safety and morale.

R. M. Engineering was one of the first companies manufacturing slotted brake disc in India.

The strength of R.M.Engineering lies in:

- Its ability to motivate and harness the capabilities of its human resource.

- Develop and nurture a strong vendor base.

- Its commitment to quality, cost, delivery, safety and customer satisfaction.

Strong in-house Research & Development, coupled with access to World Class Technology through collaboration and affiliations worldwide enables R. M. Engineering to provide the Best Braking Solutions and Castings to its customers.

Mile Stones

In this rapidly changing world, we have committed ourselves to continuous training and development. This is to prepare ourselves for larger responsibilities and future advancement, thereby maintain a knowledgeable workforce and nurture quality culture.

We grow and facilitate growing more trees, thereby contributing towards greener and healthier world.

| 2005 | R. M. Engineering was established to manufacture brass components and other engineering products. |

| 2006 | A machine was added to manufacture brake disc for passenger Vehicle |

| 2007 | R. M. Engineering are proud to announce “Strategic Alliance” With the India’s Largest Distribution Channel Jullundur Motor Agency Ltd. |

| 2008 | Developed a grinded brake disc which was the first grinded brake disc for the first time in India. |

| 2009 | High precision brake disc were introduced for high speed Vehicles. |

| 2010 | Introduced production line for producing brake disc to fulfil the demand. |

| 2011 (Oct) | More than 30 Distributors in India, Certified ISO 9001: 2008. |

| 2012 (Jan) | India’s largest product range in Brake disc & Drum. |

Environment Management

The Air Act, 1981

Air pollutant means any solid, liquid or gaseous substance (including noise) present in the atmosphere in such concentration as may be or tend to be injurious to human beings or other living creatures or plants or property or environment.

The Environment (Protection) Act, 1986

The Hazardous Wastes (Management and Handling) Rules, 1989

1. Waste water and exhaust gases as covered under the provisions of the Water (Prevention and Control of Pollution) Act, 1974 (6 of 1974) and the Air (Prevention and Control of Pollution) Act, 1981 (14 of 1981) and rules made thereunder;

2. Wastes arising out of the operation from ships beyond five kilometres as covered under the provisions of the Merchant Shipping Act,. 1958 (44 of 1958) and the rules made thereunder,

In R.M.Engineering, the problem of pollution is nearly nil. This is because no smoke as produced during the production process. Also no water or land pollution been caused by the industry.